Product Description:

VCI-HC164 VCI-HC164 Vapor Phase Anti-corrosion Wax is a coating with good anti-corrosion performance. It can provide excellent corrosion inhibition protection for metal products under harsh outdoor conditions. Solvent oil or alkaline cleaning agents can be used to remove the formation of this product. Dura mater.

Features:

Strong flexibility

Excellent salt spray protection

Good outdoor protection

Can protect a variety of metals

Good UV resistance

Superior dehydration

Hard film, thermal stability up to 200℃

Comply with MIL-PRF-16173E specification

NATO 6850-66-132-5848

NATO 6850-66-132-6099

NSN 8030-00-062-6950

NSN 8030-00-231-2345

NSN 8030-00-244-1300

NSN 8030-01-470-2601

Use field:

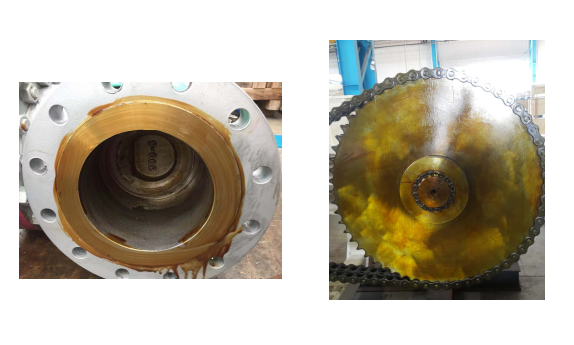

Pipe coating, parts storage, bottom coating, steel wire rope, steel plate, machined parts

Protected metals: carbon steel, stainless steel, copper, aluminum, cast iron

Usage: Brush or spray, film thickness 50-75μm, recommended for outdoor storage of uncovered parts.

Surface pretreatment:

NACE SSPC ARS

3/4 6/7 High B-2

Removal method:

Use solvent products to clean; if you spray too much, you can also use solvent products, wax cleaners or alkaline cleaners to clean.

Physical and chemical properties:

Appearance: dark brown viscous liquid

Dosage of coated surface: 7-8 ㎡/L (@75μm)

Dry film time: 12-24 hours

Touch dry time: 0.5-3 hours

Membrane type: dura mater, similar to wax

Removal method: petroleum solvent products

Carrier: solvent oil

Shelf life: 24 months@24ºC

Non-volatile matter or solid content: 60%-65%

@23ºC Viscosity: 600-5000cps (6rpm) spindle #2

VOC :347-372 g/L

Specific gravity: 0.89-0.91 kg/L

Note: The drying time of the coating will be affected by temperature, air flow and humidity.

Anti-rust properties ASTM carbon steel 1010

Salt spray protection ASTM B117 900-1500 hours

G85 2000 hours

Humidity room D1748 2500 hours

Recommended tools:

VCI-HC164: Solvent oil=3:1;

VCI-HC164 can also be used directly.

The viscosity range is 100-1000cps.

If other dilution ratios are used, please consult Rust-X.

Model: 510 vacuum/AA +

Pump: 30:1

Tip: 0.028-0.038cm

Cap: Standard

Filtration: 60Mesh high pressure

Air pressure: 80psi

Hose: 3/8"×10’ and 1/4" hose

Pressure: 2000/1700 psi(138/117 bar)

The minimum atomization pressure is 1500 psi, and it can pass through a 50-100μm wet film.

Packaging and storage: 19 liters/small bucket, 208 liters/big bucket